Nike, the renowned sportswear brand, has embraced circular solutions as part of its sustainability initiatives. Their designers use recycled materials and innovative fabrics to create sustainable products.

One prominent circular solution is Nike Grind, a program that repurposes post-consumer and post-manufacture waste into materials for new products. Nike Grind involves the collection and processing of discarded shoes and manufacturing scraps, which are then transformed into materials like rubber, foam, and fabric for use in various Nike products, promoting a closed-loop system.

In addition, Nike uses plastic bottles to make recycled polyester. Due to this initiative around 1 billion plastic bottles are removed from landfills and water every year.

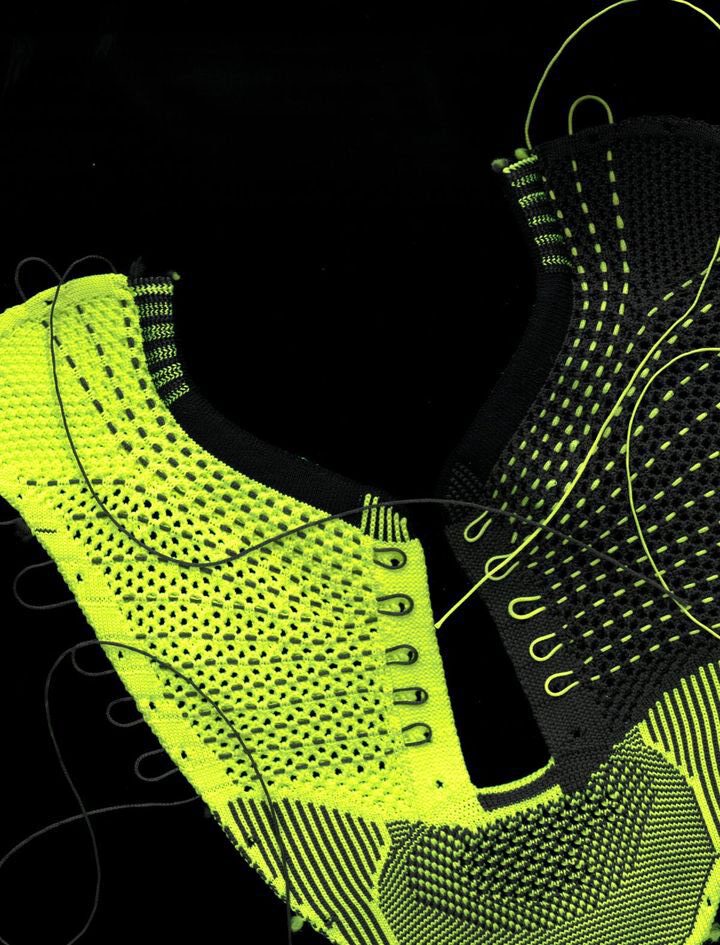

The company also uses Flyknit, a lightweight fabric made from recycled plastic. For each shoe, the company recycles about 6-7 plastic bottles to create the fabric.

Nike also has a Nike’s Refurbished program. Through this initiative, gently used shoes returned by customers are inspected, cleaned, and refurbished to meet quality standards. These refurbished shoes are then offered for sale at discounted prices through Nike’s retail channels, both online and in select stores.

Every day, Nike takes small steps that lead to great results toward a zero waste future.

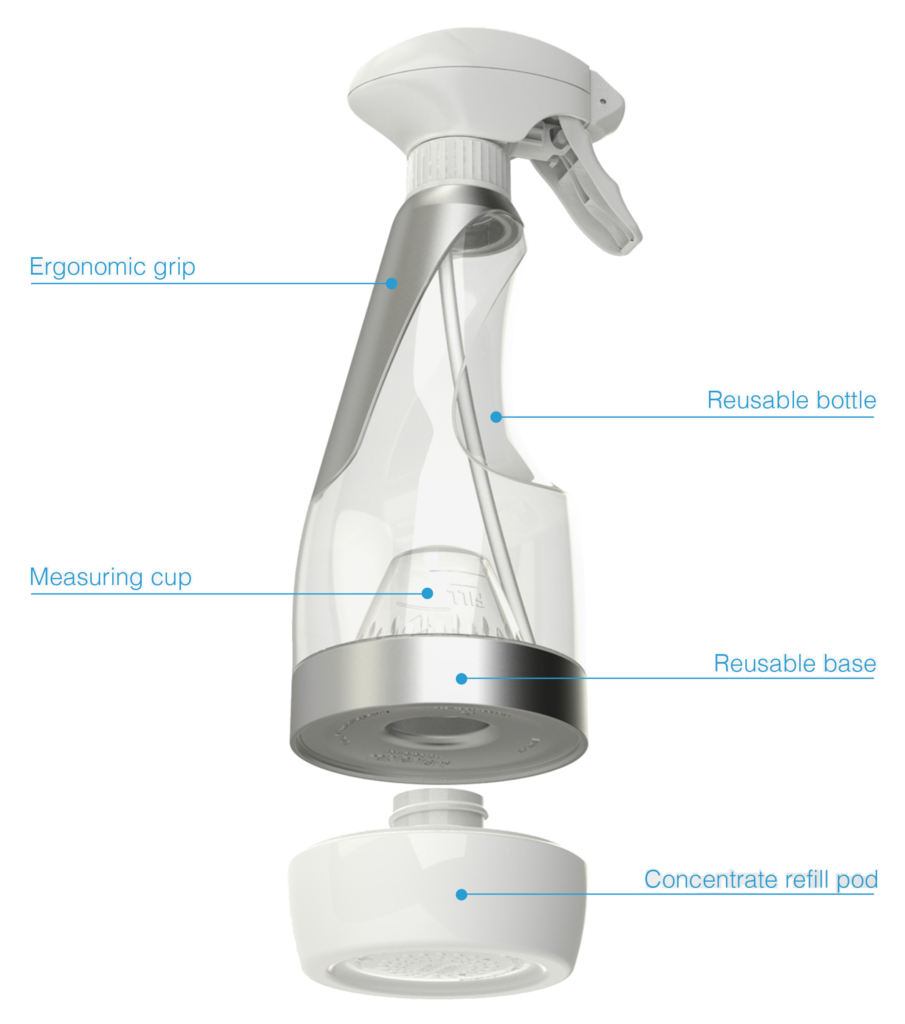

The LA-based company is an excellent example of the circular economy. Replenish tackles wasteful packaging systems with a multi-purpose reusable bottling platform.

Many of the cleaning products we buy are mostly water with only a small amount of active ingredient contained within single-use plastic packaging. In fact, a typical bottle of cleaner is 90% water and less than 10% actual valuable ingredients.

yet packaged in disposable plastic bottles, wasting resources. Replenish decided to solve this problem with its reusable spray bottles. These bottles attach to pods with liquid concentrates ranging from cleaning to personal care, meaning you use one bottle for a variety of purposes. By replacing single-use plastic bottles with refillable options, Replenish reduces packaging waste by 90%, saving both money and the environment.

Refill systems like Replenish reduce consumption of energy, plastic waste and carbon dioxide emissions by 80-90 percent compared to one-use bottles. They also avoid the need to transport water over great distances.

Loop was founded to make a huge impact on the reverse logistics system. It activates a circular ecosystem by collaborating with other companies. The company operates a global reverse supply chain – collecting used packaging from consumers and retailers, sorting and storing, and finally returning hygienically cleaned packaging to manufacturers for refill.

In partnership with major brands and retailers, Loop is currently available in the USA, Japan and France. The company aims to strengthen reverse logistics not only in a couple of countries, but also worldwide and build an international reuse ecosystem that gives second (and not only) life to single-use products.

Not using plastic isn’t the only solution for Body Shop to solve the plastic pollution problem. The company supports waste pickers, offers them access to more sanitary working conditions, a fair price and the respect and recognition they deserve. Company started using this Community Trade recycled plastic in their 250ml Shampoo and Conditioner bottles.

In 2019, Body shop reintroduced a pioneering refill scheme, giving the customers an opportunity to buy a refillable 250ml aluminum bottle and fill it with a choice of eight shower gels, and bring it back to refill once it’s empty.

A recycling program was also launched and 21 tonnes of plastic were removed from the company’s Christmas gifts. In 2021 the company started offering their most sustainable hair care yet – the bottles and tubs are 100% recyclable and are made from 100% recycled plastic.

Currently, more than 68% of Body shop’s packaging can technically be recycled.

For the past year, Radisson has minimiსed the use of single-use plastic items in its facilities. The company decided to replace plastic items with alternatives.

Mini plastic bathroom bottles in hotel rooms have been replaced by large, refillable dispensers. Initially, these items were changed in 10-10 of all large hotels of the company and 70 rooms of Park Hotel.

The next step was to replace the plastic straws and stirrers. The company found a new supplier and replaced the existing items with wooden items. In addition, plastic water bottles were replaced with glass bottles in the conference spaces, and thus approximately 1,000 bottles less water was consumed per month.

Silk Hospitality also cooperates with the Georgian enterprise “Tene”, to which it donates more than 400 kg of plastic and 2600 kg of glass waste per month.

In order to promote a circular economy, the company has completely removed single-use shower packs from hotel rooms, replacing them with reusable dispensers. In addition, the brand no longer uses water dispensers, having switched to a centralised water supply system.

With this, the company significantly reduced the consumption of plastic bottles and disposable cups. The company actively uses separated bins for waste management.

As a result of the initiatives, single-use plastic has been reduced by more than 80% on the entire territory of the hotel.